"We understand the relentless demand for uptime and scalability in this sector, and our solutions are built to deliver the robust, modular, and secure environments that the world's largest data operations require."

Founder & CEO, AVL

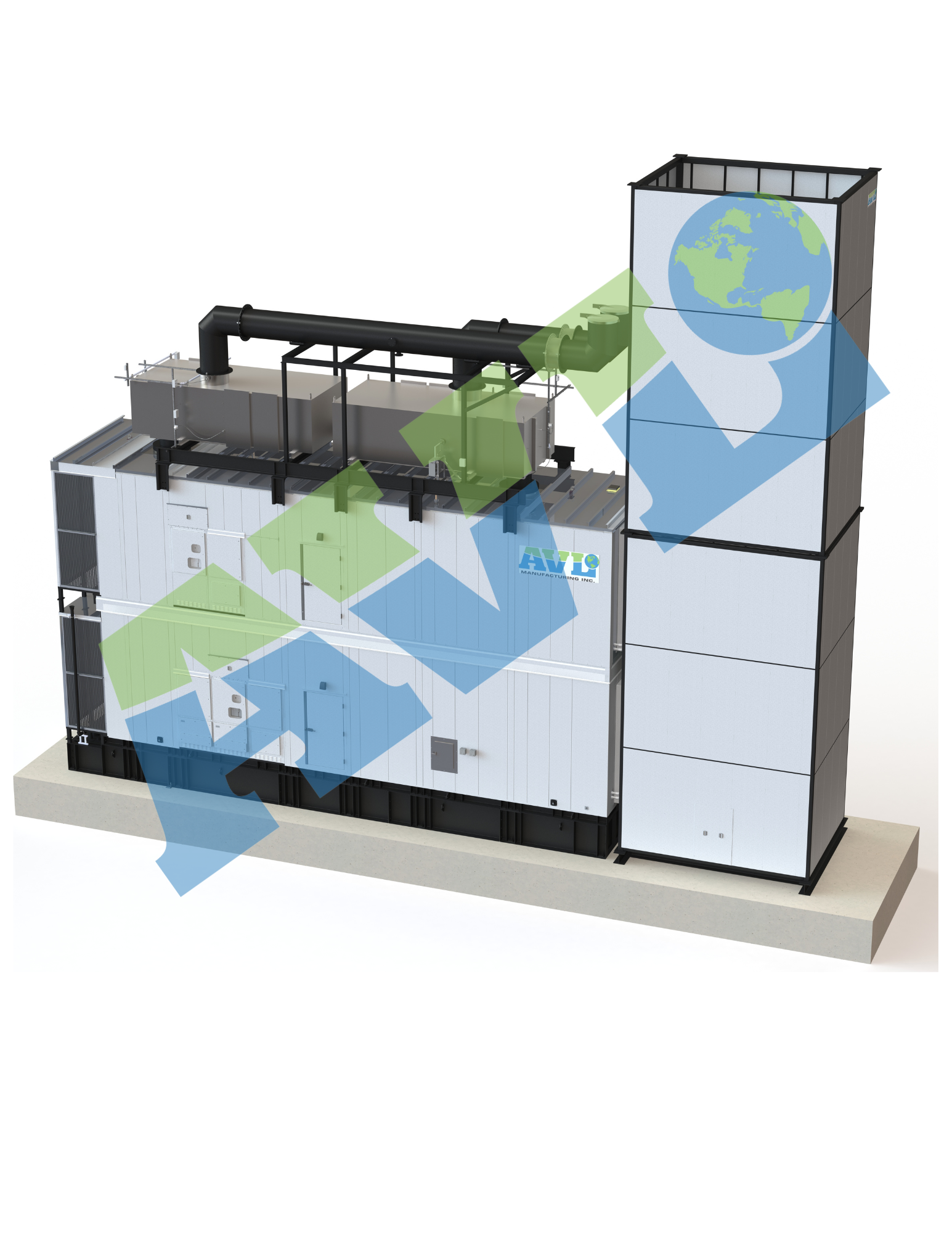

Custom Solutions for Hyperscale Data Centers

AVL Manufacturing provides reliable standby power solutions in custom enclosures designed to meet the unique needs of data center projects.

Our expertly engineered enclosures ensure:

Turnkey Systems

Tailored to specific requirements with seamless transition of power for your enclosure. Onsite testing to allow for peace of mind for backup power generation to be as easy as possible

Quality and Service

Top quality marine graded aluminum used on our enclosures, with a thorough inspection from our Quality Team, and a service team that is able to supervise, install, or work on your enclosures

FAQs

AVL is a leading manufacturer specializing in the design and fabrication of genset enclosures for hyperscale data centers, with deep expertise in high-demand industries such as Oil & Gas, Arctic environments, and custom solutions for E-Houses and Battery Energy Storage Systems (BESS).

Backed by a large in-house engineering team and nearly 500,000 sq. ft. of manufacturing space, AVL has the capability to design and build virtually anything, from complex industrial enclosures to fully integrated power systems, while consistently meeting the highest standards of quality, durability, and performance.

AVL works with a wide range of genset manufacturers and models to meet diverse project needs. Our enclosures are compatible with most major brands, including Caterpillar, Cummins, MTU, Kohler, Generac, and more. We design custom enclosures for gensets ranging from 250 kW up to 4 MW, covering backup power, prime power, and Combined Heat and Power (CHP) systems. This ensures optimal protection and performance tailored to your specific genset size and configuration.

For backup power systems, design typically take 4 to 6 weeks. More complex solutions like Combined Heat and Power (CHP) may require 2 to 3 months, depending on size and complexity. Production currently averages about one enclosure per month per production slot, with our facility having 50 slots monthly. These are large, 50-foot enclosures built for hyperscale data centers and other demanding applications. Throughout the process, our engineering and production teams collaborate closely with you to ensure your enclosure is delivered on time and meets your exact specifications.

AVL enclosures are engineered for fast, straightforward installation using standard lifting and rigging equipment. Removable bolt-on components and strategically placed lifting lugs help reduce shipping dimensions and make on-site handling more efficient. Once delivered, AVL’s experienced Service team is available to provide on-site supervision, full site and installation, along with full support during and after the warranty period.

Yes! While it’s always best to design and plan for future changes upfront, AVL enclosures are built with solid aluminum walls and roofs and a strong structural frame that supports modifications after installation. Whether you need to adjust ventilation, add access points, or integrate new equipment, our experienced service team—supported by in-house engineering—is fully equipped to perform these changes on-site with minimal disruption, keeping your system flexible and future-ready.